Spaghetti Coil

I was in the kitchen making coffee, I happened to see the Spaghetti jar on the worktop, that gave me an idea to use one for a former, so next time I went shopping, I picked one up.Here's the story

I first built a coil using a rotary spark gap using a small DC motor, the speed control was a regulator module

The regulator failed, so i converted to a static spark gap

Input voltage: 250V

Input Frequency: 50Hz

Output voltage: 11000V

Output current: 18mA

Primary turns: 10 (just some copper wire at the moment)

Secondary

Turns: 788

Wire: 30awg

Diameter: 4.5 inches

Height: 9 inches

Topload: just the aluminium lid 4.5 inches dia

Capacitor: 8nF

-------------------------------

Building the coil:

While making myself a coffee, my eyes wandered around the kitchen, then i saw it, a spaghetti jar. When I went to Tesco I found one for £4, it's 280mm high and 110mm diameter.

I proceeded to wind on as near as possible to 1000 turns of 0.35mm wire (haven't counted the turns), then construct a base for it.

Primary is 10 turns of 2.5mm csa single strand house wire, the base may get used for other coils. RSG is below the top plate, it's a motor from a scrapped printer, the rotor is a tape deck idler wheel with the rubber removed, but is insulated from the shaft of the motor. The 4 posts are audio jack tops (i had a load of them i don't use) with a M4 bolt drilled though.

The bottom layer of the base is reserved for capacitors, though i'm not sure what type, as it stands i'll probably test it using my Leyden jar caps on my control box described elsewhere.

spag1.jpg

The RSG

The Primary

Assembled

With Toroid made from large vacuum cleaner hose covered in foil

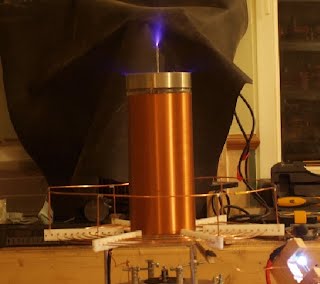

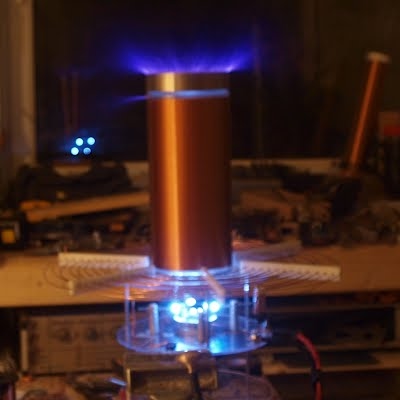

Latest Pics These were taken on long exposure of about 4 seconds, I placed a woodscrew on top as a breakout point, you can also see a corona on the edge of the lid, I used a temporary SSG instead of the RSG

Nice arc and corona

In this one I introduced the earthing wand in the middle of the exposure which is the gold coloured ball above the spark, that probably explains the arcing down the side as I brought in the wand

A closer view, although you can see the RSG below the coil, I decided to try a static gap, as can be seen bottom right, I need to do more work on the RSG

I remade the RSG, instead of 4 sparks per rotation, it is now 12, it's more stable mechanically as the old one wobbled a bit meaning i had to adhust for a larger gap. I added a bearing to support the rotor, and direct drive from motor.

As you can see, there are 6 contacts on the rotor, and 4 static

Corona at full power 2 extra turns were added to the primary, so is now tapped at 12 turns

You will notice just below the lid there's a blue glow, that's just the light shining up through the jar from the RSG and not internal corona.

On test with the woodscrew as a breakout point, i measured the spark just about reaching 200mm.

You may freely link to any content or page. You may not hotlink any images etc You may copy any snippet of information providing you credit me with the creation